Authors: Blandine Velut, Vincent Crave

Date of publication: 10/01/2023

Context

Cell culture is a widely used in vitro tool for improving our understanding of cell biology, tissue morphology, mechanisms of diseases, drug action, protein production and the development of tissue engineering. Most research regarding cell biology is based on experiments using two-dimensional (2D) cell cultures in vitro. It is estimated that more than 75% of cell culture work is currently performed in 2D.

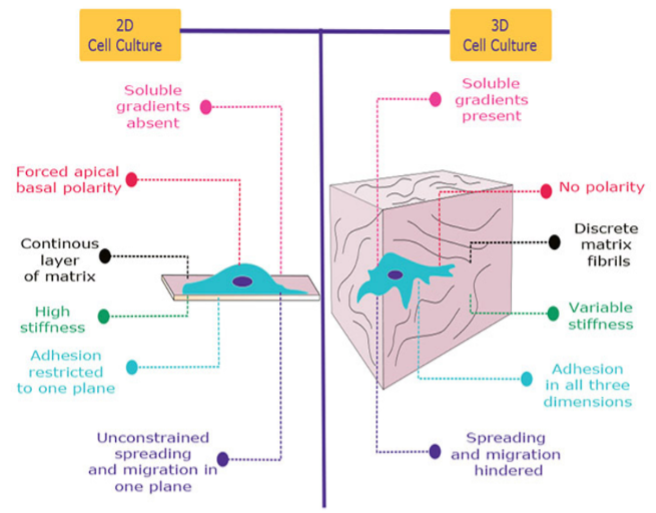

These models are simple to use, operate well with high-throughput systems, and can be quickly integrated into automated workflows. However, 2D cultures have a number of drawbacks. Cells in the body grow in three dimensions and are constantly interacting with other cells and extracellular matrix proteins (ECM). These interactions are known to regulate complex biological functions such as cell migration and apoptosis, which are typically lost in 2D cultured cells. Furthermore, these models illustrate changes in cell morphology, polarity, and division mechanism. As a result, they are a poor representation of in vivo conditions (Fig. 1).

These disadvantages prompted the development of three-dimensional culture (3D) models which are better at mimicking in vivo conditions. Many new predictive in vitro cell culture 3D models scaffolds, low adhesion plates, micropatterned surfaces, or hanging drops) have recently emerged (Fig 1) and have been lauded by medical authorities such as the FDA and the EMA. Unfortunately, because these new technologies are more complex, they frequently require the services of dedicated experts. Furthermore, experiments based on 3D models are frequently difficult to automate.

To address large-scale analysis in a more physiological 2D environment, alternative concepts such as stiffness-controlled surfaces (soft plates) have recently emerged. The soft plate improves 2D cell culture by providing a mechano-transduction substrate that serves as the basis for the micro-environment, allowing the cells to be placed in more physiological conditions. The enhanced 2D models (2,5D) are close to 3D, but without the biological complexity, making it an attractive platform for routine and large-scale analysis.

Science & Tech

Mechanical environment & Stiffness control

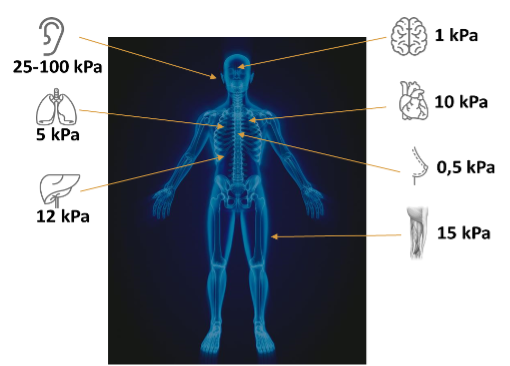

The mechanical environment, and more specifically mechano-transduction, has an impact on several biological processes, including the initiation of signaling pathways that lead to gene expression, protein synthesis, and cellular phenotype change. Cell culture plates, which are commonly used in pre-clinical studies, are 106 times more rigid than any organ (Fig 2). It is anticipated that the entire signaling pathway will be affected, and basic cellular functions such as growth, survival, apoptosis, differentiation, or morphogenesis will be dysregulated or deregulated.

Following the initial discovery, several research teams have developed home-brewed stiffness-controlled cell culture surfaces. They better mimic the interactions between cells and supporting tissues, providing a more physiological representation of mechano-transduction, and facilitating the conversion of mechanical stimuli into biochemical signals.

Furthermore, by tailoring the rigidity of the cell culture plate to the studied organ, the cells grow in more physiological and mechanical conditions. Soft plates are made by applying a thin layer of hydrogel or polymer (polyacrylamide, silicone) to the bottom of cell culture well plates (microplate, petri dish, or coverslip). By adjusting the density of the gel layer, the rigidity can be tailored to the organ under investigation. The surface of the gel can be functionalized to facilitate ECM coating, allowing control over surface chemistry as well as rigidity. The plates can be uniformly rigid, but they can also have patterns like rigidity gradients or micropatterns. Soft plates are mainly used for basic research projects but are starting to be implemented in many stages of drug discovery.

Main applications

Stem cell and oncology research were among the first to use soft plates.

Multiple peer-reviewed publications (Engler et al. Cell, Kasten A et al. Cell Biochem, Subramanian A et al. Journal of Biomedical Materials Research) have demonstrated that the stiffness of culture plates affects stem cell differentiation: high rigidity promotes pluripotency maintenance, while low rigidity promotes differentiation. Controlling plate rigidity can therefore aid in cell engineering by improving control over the differentiation process, resulting in more reproducible results for subsequent research. Whereas in oncology research, increased stiffness of tumor cells is well established, notably allowing organ palpation as a non-invasive diagnostic method for multiple cancer types. In fact, the stiffness of the microenvironment is important in the development and metabolism of lung and breast cancer cells. Meanwhile, controlling culture plate rigidity to study cancer cells replicates in vivo mechanical forces, thus improving drug discovery results transposability. In the future, personalized medicine may benefit from this innovation by developing therapeutic solutions based on cancer progression as measured by the stiffness of tumor cells.

Malignant progression is caused by the tumor’s integrated response to extrinsic physical and chemical cues such as microenvironment-induced gradients, including environmental stiffness. In recent years, organoid platforms have greatly expanded the ability to dissect cellular crosstalk by providing more relevant in vitro models. As microenvironmental elements are incorporated into these models, they will most likely be critical tools for probing the complex extrinsic signals that govern cell fate. Even with these intricate 3D models, it is critical to incorporate the mechanical environment and the effect of mechano-transduction in order to provide a more realistic representation of physiology. Moreover, the use of soft plates in conjunction with 3D models would increase the relevance of the models without necessarily increasing complexity.

Indeed, the cosmetic industry places considerable emphasis on skin and tissue stiffness. Previous studies that highlighted fundamental questions regarding cell migration or drug effects on the cytoskeleton (Smith JT et al. Cell, Yeung T et al. Cell Motil Cytoskeleton) have been sidetracked by cosmetic R&D. Consequently, the combination of soft plates with a stiffness gradient and Traction Force Microscopy (TFM) significantly increases the potential for studying cosmetic actives with lifting or healing properties.

Market

- Market overview

The stiffness-controlled (soft plate) plate market is still in its infancy, which means that there is no reference point to frame and estimate the size of the market. However, they can be classified as a subset of two larger markets: the Cell Culture market and the Drug Discovery market.

Based on the applications currently identified for soft plates, they could become a substitute for Petri dishes and microplates at various stages of oncology research, including stem cell culture, organoid/spheroid culture, and HCS. In 2019, the global market for cell culture consumables was estimated to be USD 1.5 billion, with Petri dishes and microplates accounting for 65.2%, or USD 978 million. We estimate the total addressable market for soft plates to represent 5% of the Petri dishes and microplate segment, accounting for approximately USD 48,9 Million.

The stage of Drug Discovery most likely to factor in the importance of microenvironment and mechano-transduction is screening and more specifically high throughput screening (HTS). In 2020, the HTS segment accounted for 39% of the Drug Discovery market, with consumables accounting for the remaining 19% (USD 2,8 Billion). The consumables market includes not only plates but also reagents, which represent a significant proportion. The soft plate market within the global Drug Discovery market will account for approximately USD 70 million in 2026 based on the hypothesis that 2,5% of screening experiments will use soft plates.

The estimations built from the two distinct approaches provide a rough estimation of the market size for soft plates in the range of USD 55 million.

- Market players

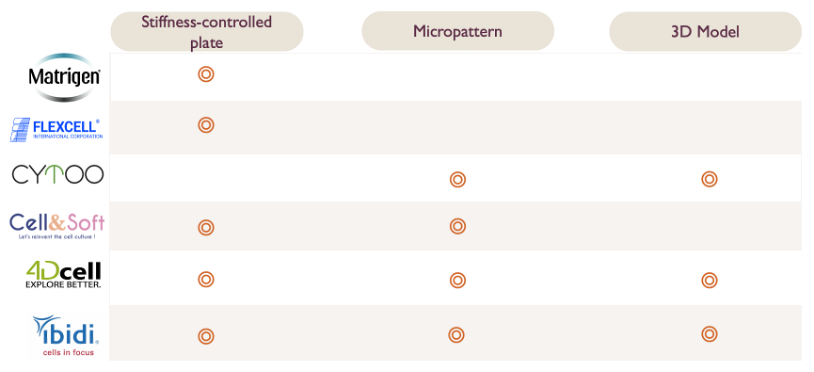

The stiffness-controlled plate market is limited to a small number of stakeholders. As a matter of fact, major players in the cell culture market, such as Corning or Greiner, have yet to invest in the technology or add soft plates to their product portfolio. Meanwhile, Matrigen is the market leader in the manufacture of stiffness-controlled plates. The company, headquartered in Brea (CA, USA), was founded in 2010 by Dr. Justin Mih of Harvard University. Matrigen manufactures plates that are coated with a polyacrylamide hydrogel. Their products are perfectly compatible with microscopy and HCS applications. In 2019 their revenue was estimated at USD 6 Million.

Flexcell was founded in 1987 in Burlington, CA (USA). The company has over two decades of experience developing technologies that use vacuum to stretch cells. Flexcell’s revenue in 2019 was estimated to be USD 13 million. They entered the stiffness-controlled plate market the following year with the debut of its new silicone-based technology, CellSoft. Given that these products are not yet listed on the Flexcell website, they will become the company’s trademark

Smaller players have emerged and are differentiating themselves through the development of novel concepts that incorporate stiffness-controlled surfaces with micropatterning and 3D modelling (Fig. 3). Cytoo, a French start-up based in Grenoble (France), was founded in 2008 by François Chatelain and Alexandra Fuchs. Since its inception, the firm has raised more than USD 16.5 million. Cytoo’s expertise is in photolithography-generated micropatterns, and the company is developing sophisticated cell models for the pharmaceutical industry using the micropattern technology platform.

Cell&Soft (Grenoble, France) is a French start-up company founded in 2018 based on eight years of research and development led by Camille Migdal of the CNRS Microelectronics Technology Laboratory and Grenoble Institute of Biosciences and Biotechnologies (CEA BIG). Cell&Soft offers a portfolio of innovative cell culture plates coated with polyacrylamide hydrogel and featuring adjustable stiffness based on polymerization density. Cell&Soft can tune the plate stiffness to the organ being researched and provides a large combination of rigidities (11). Additionally, the soft plates can be paired with micropatterns to create a unique system for controlling the mechanical environment on a cellular level.

Likewise, the French company 4Dcell (Paris, France) provides a complete solution (system), which includes micropattern, cell culture plate stiffness control, and 3D cell containment. Maël Le Berre and Cyril Cerveau (ESIEE Paris) founded 4Dcell in 2016, and the company has expanded its product line to include micropattern kits in addition to plates and strips.

Ibidi (Berlin, Germany), created in 2001 by Dr. Valentin Kahl of the Technical University of Munich, also integrates a number of technologies to enhance 2D and 3D cell assays. The German company, based in Gräfelfing, supplies rigidity-controlled plates with micropatterns. Its annual revenue is around USD 13 million.

In a nutshell

More physiological cellular models are being explored than ever before to optimize drug candidate selection and bridge the translational gap between preclinical and clinical settings. Though multiple cutting-edge 3D technology platforms are being adopted (spheroids, organoids, lab on a chip, and microfluidic), they typically lack flexibility and do not fully comply with industry standards. 2.5D technologies, such as micropatterning and stiffness-controlled platforms, are being marketed as a low-cost alternative that will enable the pharmaceutical industry to continue performing large-scale research. Most of these innovations are being driven by startups spun out of universities. Going forward, the ability to demonstrate the technology’s potential and scale it up will be critical to the adoption of drug screening and routine applications. This would eventually capture the interest of major players in a market worth approximately USD 55 million in 2024.

Any questions?

Need a strategy for establishing and growing your business? Limited in capacity to implement marketing, sales and distribution channels? Whether you’re trying to find your ideal market, launch a product, or expand your existing business, get in touch with our team now, and experience the Novoptim difference.

Get in touch